Laser MicroJet Benefits

Synova offers fast and accurate laser machining solutions for the tool manufacturing industry.

Laser MicroJet (LMJ) systems are able to cut a wide range of materials such metals, ceramics, ultra-hard materials and carbide substrates as well as non-conductive materials such as SCD.

The laser cutting systems with 3 axes are ideal for 2D cutting, drilling, grooving or slicing of PCD, MCD, PcBN or CVD diamond tool bits, leaving smooth cutting surfaces and sharp edges.

The 5-axis machines enable high-precision 3D ablation (shaping) for cutting single or multiple clearance angles and chamfering K-land edges. Furthermore, the LMJ technology allows homogeneous step-free cuts between diamond layer and carbide.

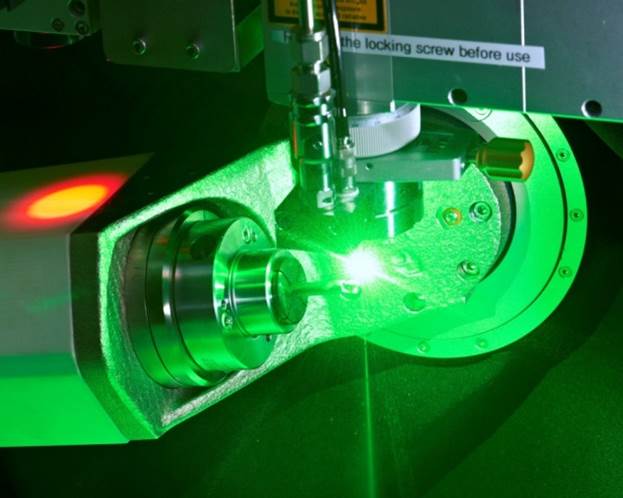

All machines are based on Synova’s hybrid water jet/ laser method (LMJ) that combines the advantages of water and laser cutting into one operation. The laser beam is entirely contained within the water jet as a cylindrical beam, similar in principle to an optical fiber, resulting in perfectly parallel kerf walls. Contrary to results achieved by conventional lasers, Synova’s wet approach offers a less aggressive cutting process without heat affected zone (HAZ) and micro-cracks that can weaken the material’s fracture strength. Notably, since the LMJ produces damage-free edges, it eliminates the need for extra processing steps, such as etching, grinding or cleaning and therefore reducing manufacturing costs.

Main Applications

Cutting diamond tool inserts for milling machines/ drilling machines

-

A. PCD drill bits

A. PCD drill bits

A. PCD drill bits

A. PCD drill bits

-

B. PCD drilling tool insert

B. PCD drilling tool insert

B. PCD drilling tool insert

B. PCD drilling tool insert

-

C. PCD tool inserts

C. PCD tool inserts

C. PCD tool inserts

C. PCD tool inserts

-

D. Tool insert (MCD)

D. Tool insert (MCD)

D. Tool insert (MCD)

D. Tool insert (MCD)

-

E. Clearance angle (MCD)

E. Clearance angle (MCD)

E. Clearance angle (MCD)

E. Clearance angle (MCD)

-

F. Surface and edge quality by LMJ

F. Surface and edge quality by LMJ

F. Surface and edge quality by LMJ

F. Surface and edge quality by LMJ

https://www.synova.ch/applications/tool-manufacturing.html#sigProId7f497ef2e2

Customer Sample Request Form

If you are interested in seeing how the Laser MicroJet® can improve your manufacturing processes, please send us a short description of your application (material, thickness, process, requirements).

Therefore please use the electronic form CSRF available in English, German or French: