The Unique Strenghts of the Laser MicroJet

No Material Damages

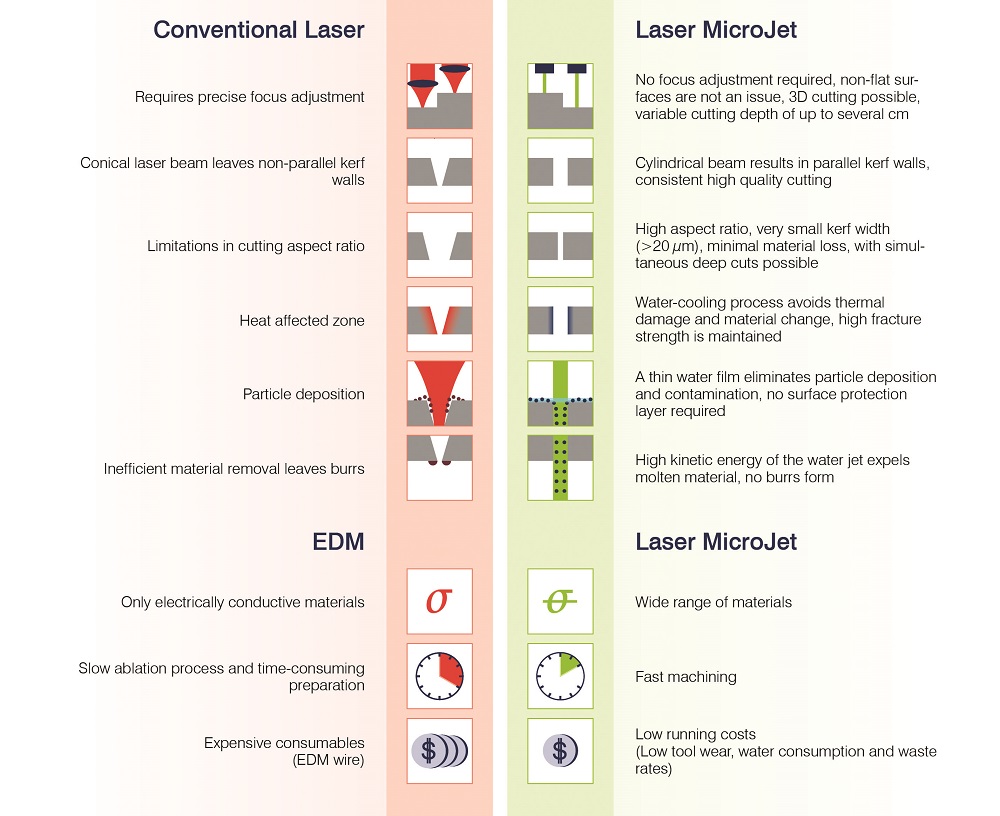

Thanks to the water jet cooling capability there is virtually no heat damage (no HAZ) and material change. The ablated material is removed with the water flow leaving clean surfaces and neither depositions nor burrs.

Very Large Thickness Range

The LMJ can cut a wide variety of material thicknesses - from a micron to centimeters. It can cut up to 30 mm thick diamond or silicon carbide or drill up to 15 mm thick superalloys (hole diameter 800 µm).

A Unique Parallel Laser Beam

The cylindrically guided lasers used in Synova’s machines are highly accurate tools which can achieve tight, parallel kerfs (>25 µm) - meaning no taper - with an absolute precision as low as +/- 1.5 µm, resulting in appreciable material savings.

High Cutting Speed - Low J/mm3

The usage of industrial high-power lasers enables high cutting speeds while ensuring quality standards, for example up to 45 mm/min in 7mm thick silicon or 5 mm/min in 4 mm CVD diamond.

Wide Range of Materials

The water jet guided method allows machining of a broad range of materials (conductive or non-conductive). Since it's a very gentle process, the LMJ is particularly well-suited for machining brittle and hard materials or composites that are easily damaged using traditional cutting processes.

- Ceramics

- Composites

- Metals and alloys

- Diamond

- Hard materials

- Semiconductors

Download our technology brochure here: