Laser MicroJet Benefits

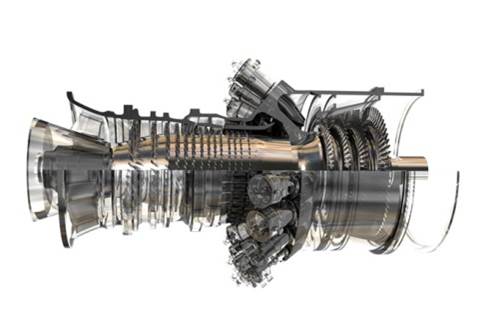

Synova’s advanced Laser MicroJet (LMJ) systems with 3 or 5 axes are perfectly suited for machining high-precision parts in the energy and aviation industry.

The hybrid water jet/ laser method provides precise through-hole drilling in hot section components of industrial gas turbines for cooling that require special materials such as thermal barrier coatings. Superalloys with or without thermal barrier coating can be processed in one simple step, without cracks or delamination in the ceramic coating and extremely low recast in the metal structure.

The LMJ systems are able to drill round and shaped holes (square, trapezoidal and inclined) at high process speed and with excellent quality at the entry and exit of the hole as well as on the sidewall.

Compared with conventional laser methods, the technology’s “wet” approach offers a less aggressive cutting process without causing heat damage. The water jet continually cools the cutting zone and efficiently expels contaminants from the work piece surface. Any kind of metal, hard material and most ceramic-matrix composites, for example zirconia, alumina or silicon carbide can be machined. The running costs of the LMJ systems are low since there is no tool wear, very few consumables and low waste rates.

Main Applications

- Drilling of cooling holes in hot section components of industrial gas turbines (e.g. blades or vanes with or without thermal-barrier coating):

- Shaped diffusor holes (square, trapezoidal, inclined)

- Round holes

-

-

A. Machined turbine blade

A. Machined turbine blade

A. Machined turbine blade

A. Machined turbine blade

-

B. Front side of diffusor hole

B. Front side of diffusor hole

B. Front side of diffusor hole

B. Front side of diffusor hole

-

C. Back side hole

C. Back side hole

C. Back side hole

C. Back side hole

-

D. Hole drilling quality

D. Hole drilling quality

D. Hole drilling quality

D. Hole drilling quality

-

E. Cross section

E. Cross section

E. Cross section

E. Cross section

https://www.synova.ch/applications/energy-aviation.html#sigProId6346e7bcd0

2. Cutting of ceramic matrix composite (CMC) parts

-

A. Drilled CMC - Entry hole

A. Drilled CMC - Entry hole

A. Drilled CMC - Entry hole

A. Drilled CMC - Entry hole

-

B. Drilled CMC - Exit hole

B. Drilled CMC - Exit hole

B. Drilled CMC - Exit hole

B. Drilled CMC - Exit hole

https://www.synova.ch/applications/energy-aviation.html#sigProIdb91d58d619

Customer Sample Request Form

If you are interested in seeing how the Laser MicroJet® can improve your manufacturing processes, please send us a short description of your application (material, thickness, process, requirements).

Therefore please use the electronic form CSRF available in English, German or French:

Testimonial

"Despite the limited time I could get a first in-depth insight into the LMJ potential for ablating TBC and superalloy materials. We could also identify first promising process windows for ablation at high removal rates, particularly for metals, with quality still likely to meet our typical production requirements.

The LMJ process has a particular strength in the processing of superalloy metal material. Here the benefit from the local cooling by the water jet and the tolerant focus position are real assets, allowing to realize high removal rates at good quality."

(Alstom (now GE) after first LMJ machining tests)

Applications on Customer Site

This video shows precise through-hole drilling of a thermal barrier coated GE turbomachinery component using Synova's Laser MicroJet® technology. This technology is being utilized in an innovative manufacturing machine, developed through the partnership of GE, Synova and Makino Milling Machine.

Advanced manufacturing: Through-hole drilling of a TBC coated GE turbomachinery component

Learn how Synova's high-precision Laser MicroJet machine helps GE Power make jet engine and gas turbines more efficient:

GE Reports: Watch This Water-Guided Laser Machine Cut the Tiniest holes in the Toughest Metals