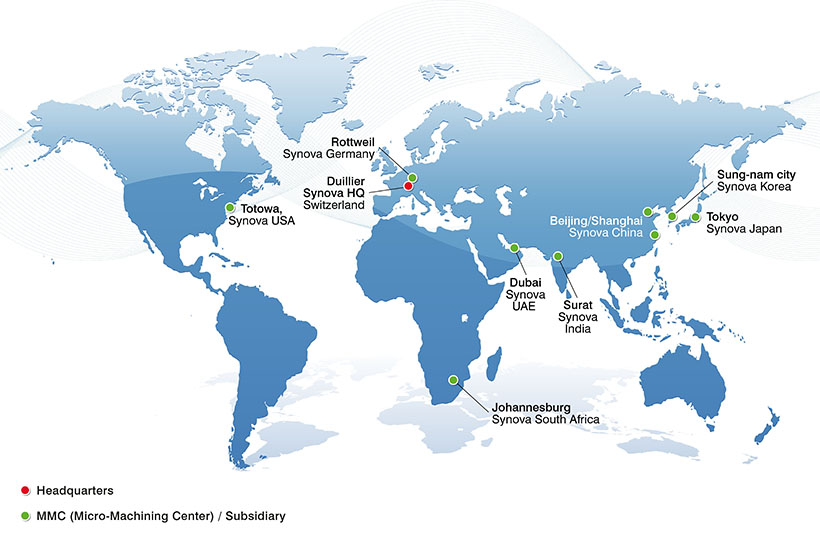

SYNOVA established wholly owned local subsidiaries in the USA, Japan, India, Korea, Germany, UAE, China and South Africa for optimized customer support. These have since been expanded to include micro-machining centers (MMCs).

These subsidiaries serve as competence centers for demonstrations, sample testing and application developments. In addition, they offer regional micro-machining services for the industrial, diamond and semiconductor industries. The establishment of customer support centers in key locations throughout the globe fortifies Synova’s expansion efforts, providing an optimum environment for the company to better serve its worldwide customer base.

Germany

The German micro-machining center is located in Rottweil (Baden-Württemberg) and serves the German market, Austria and the Benelux countries. The MMC features a showroom where job shop production and sales activities take place. Additionally, it provides laser processing services, including cutting jobs, application testing, and on-site machine demonstrations. Two Laser MicroJet (LMJ) systems are available for this purpose: the LCS 303 laser cutting system for 2D machining of workpieces up to 300x300mm in size and the 5-axis laser machining center LCS 305 for 3D machining.

India

The Synova MMC India is based in Surat, the world’s largest diamond cutting and polishing center. The MMC disposes of multiple diamond cutting systems with Laser MicroJet (LMJ) technology (DCS 300, DCS 150, DCS 50, DCS 30, DaVinci Diamond Factory), thereby covering almost the entire spectrum of diamond sizes that the industry processes. With its unique LMJ technology, Synova offers diamond manufacturers unprecedented benefits, such as minimal weight loss, fast cutting times, reduced damage to expensive rough stones and overall higher yields. The MMC in Surat is also available for job shop cutting services.

Japan

For its MMC in Tokyo, Synova teams up with Makino, a renowned industrial machine manufacturer. This partner center bolsters Synova’s commitment to supporting its customer base in Japan and continues to fuel industry adoption of its Laser MicroJet® technology. Synova’s sales and support center enables Synova to strengthen its foothold in a region that is home to some of the world’s largest electronics manufacturers.

.jpg)

Korea

Synova opened its MMC Korea in Sung-nam city, the geographic center of Korea close to Seoul and to world-leading semiconductor manufacturing companies. Since it’s opening in 2012, the MMC has been very well received by customers in the semiconductor, LED, FPD, and electronics industries. Not only semiconductor materials such as Si, SiC or GaAs, but also thin metals and ultra-hard materials such as PCD or CBN can be processed with the LDS 300 system on site. Customers also utilize the center’s job shop service for low volume productions.

.jpg)

South Africa

Situated in Johannesburg, the office serves as a strategic foundation in Synova's efforts to expand its presence in the African region. This facility is fully equipped to address the distinct requirements of industries operating in sectors such as semiconductors, diamonds, and industrial manufacturing. Furthermore, it assumes a crucial role in elevating Synova's after-sales services, ensuring that customers receive comprehensive assistance and support. This initiative underscores Synova's commitment to fostering long-lasting partnerships to its clientele throughout the African region.

UAE

The UAE micro-machining center is located in the Almas Tower in Dubai, the leading hub for diamond trade. The diamond center of excellence with its 5-axis DaVinci machine offers job shop cutting services for rough diamonds ranging from sawing, pie cutting and drilling to, in particular, faceting and fancy shaping.

USA

The U.S. micro-machining center in Totowa, New Jersey, supports customers throughout the North American region. The MMC is equipped with four Laser MicroJet systems (LCS 305, LCS 150, DaVinci Diamond Factory, LDS 200) that are ideal for 2D and 3D machining of metals and ceramics for industrial and medical applications, cutting of hard materials such as monocrystalline and polycrystalline diamond (PCD, MCD), CVD diamond and cubic boron nitride (CBN), silicon carbide (SiC) as well as semiconductor dicing of silicon and III-V materials. Diamond-processing services are also offered on the DaVinci system. The MMC is particularly well suited for feasibility testing, application development, early hardware builds, qualification runs, prototyping and low volume productions.