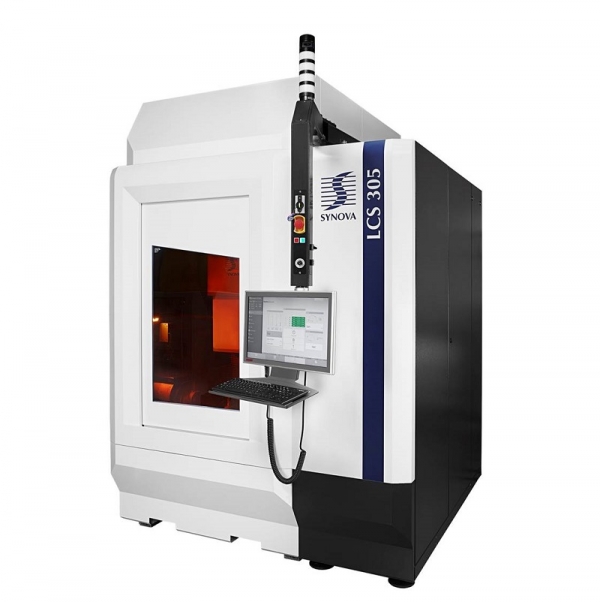

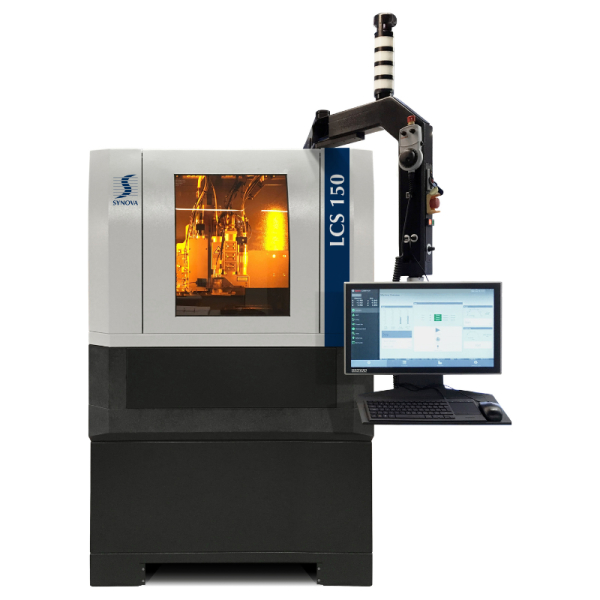

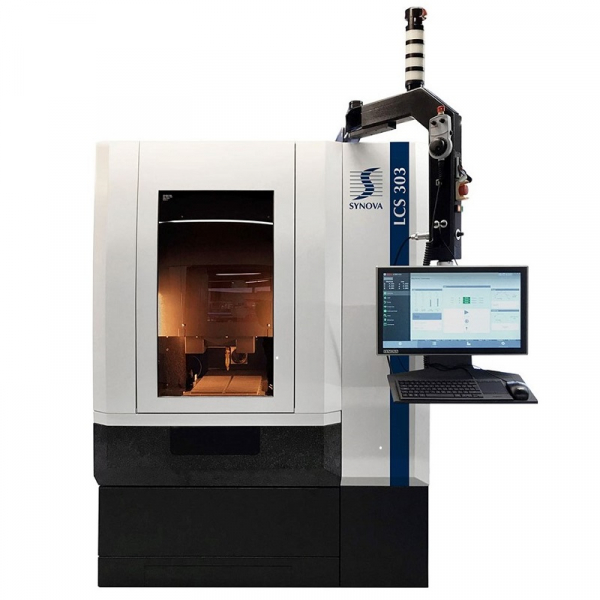

Synova’s laser cutting machines offer fast and accurate laser machining solutions for the tool manufacturing industry. Laser MicroJet® (LMJ) systems are able to cut a wide range of materials such metals, ceramics, ultra-hard materials and carbide substrates as well as non-conductive materials such as SCD.

The laser cutting systems with 3 axes are ideal for 2D cutting, drilling, grooving or slicing of PCD, MCD, PcBN or CVD diamond tool bits, leaving smooth cutting surfaces and sharp edges. The 5-axis machines enable high-precision 3D ablation (shaping) for cutting clearance angles and chamfering K-land edges.