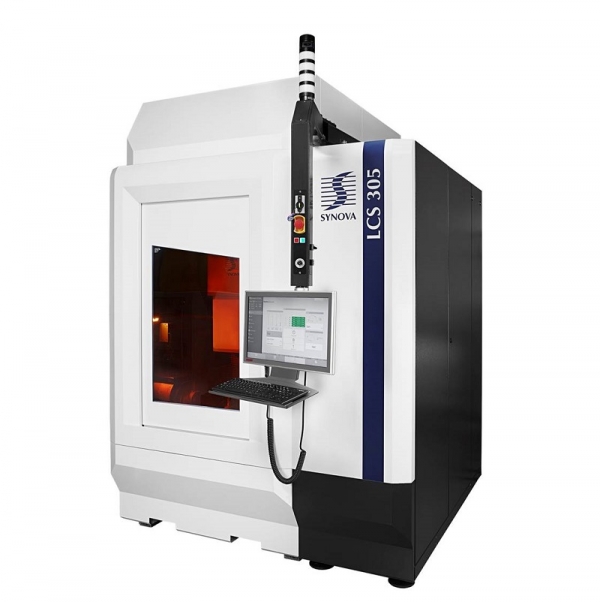

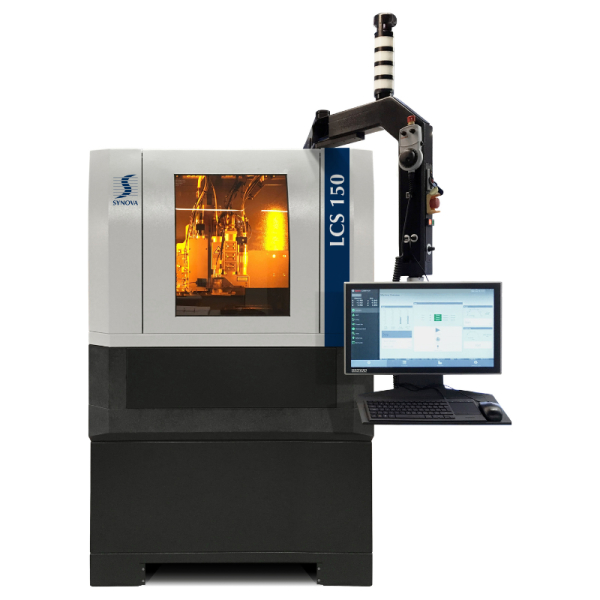

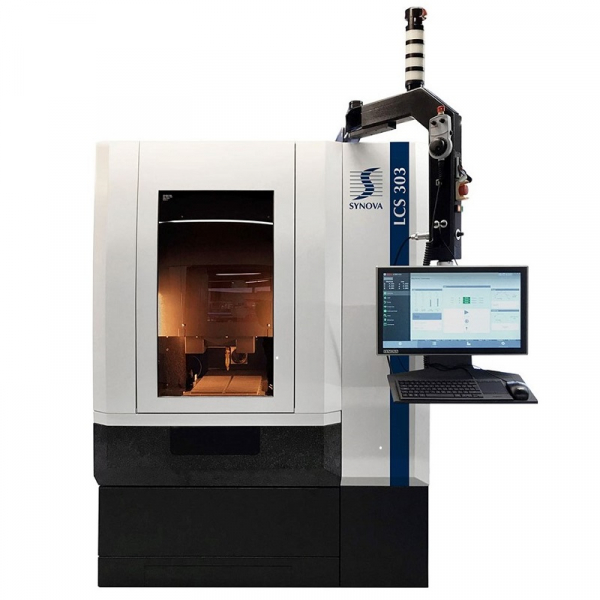

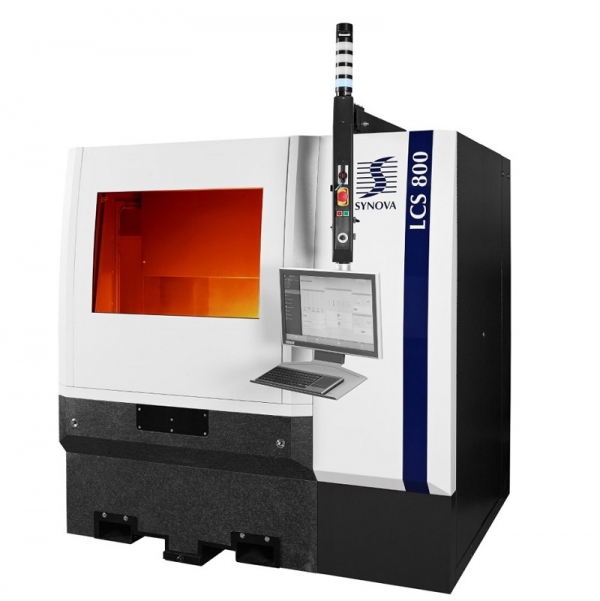

Synova’s advanced laser cutting systems, featuring our water jet guided Laser MicroJet® (LMJ) technology, perform fast, accurate, omni-directional cutting with no chipping, burrs, deposition, contamination, thermal damage, material changes or mechanical stress.

Thanks to the versatile LMJ technology, Synova’s metal cutting machines can be used for a broad range of processes, including cutting, drilling, slicing, shaping, edge grinding, grooving, milling, trenching or engraving -depending on the particular machine and number of axes.