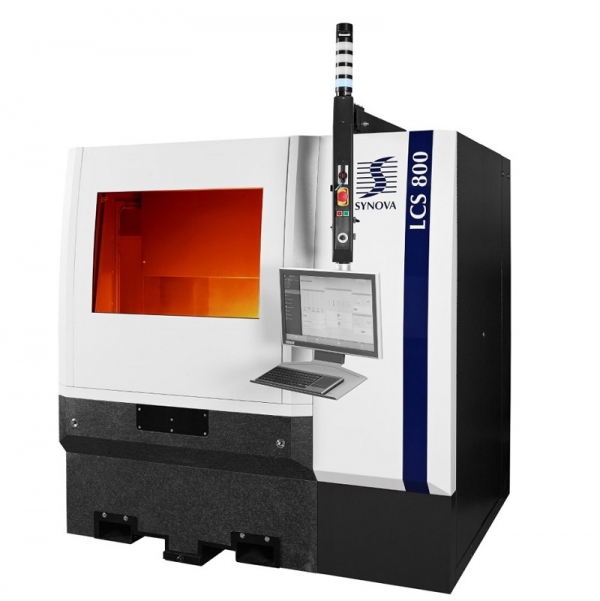

The 3-axis laser cutting machine LCS 800 with integrated Laser MicroJet® technology is a robust and versatile system conceived for a multitude of high-precision cutting and drilling applications in different industrial sectors. The large mounting table allows machining of virtually any part size and is suited for small series and prototypes but also for large volumes.

Main applications include machining of semiconductor equipment sub-assemblies, metal masks and other components made of metal, ceramics or composites (e.g. silicon carbide, CFRP).

The LCS 800 has an intuitive and fully integrated system control interface with touchscreen functionality. The offset calibration system integrates automatic laser-nozzle alignment, automatic jet angle correction (both optional) and laser power control.

Materials

Ceramics & Composites: Silicon carbide (SiC), silicon nitride (SiN), ceramic-matrix composites (CMCs), CFRP, Zirconia (ZrO2), HTCC/LTCC, aluminium nitride (AlN), aluminium oxide (Al2O3)

Metals: Stainless steel, aluminum, copper, nickel, titanium, superalloys, etc.

Ultra-hard materials: Polycrystalline CBN (PcBN), polycrystalline diamond (PCD), single crystalline diamond (SCD), CVD diamond, natural diamond, tungsten carbide (WC)

Operations

2D cutting, drilling, slicing, slotting, grooving, trenching, milling, engraving, profiling

Key Benefits

- Sharp and Smooth

- Cylindrical beam resulting in parallel kerfs (no V-shape)

- Smooth cutting surfaces and sharp edges

- Virtually no heat impact thanks to water jet cooling capability

- Fast and Accurate

- Cutting of 10 mm CBN in 26.5 mm/min.

- High mechanical precision with a tolerance of less than +/- 8 μm

- Very small kerf width (down to 30 μm)

- Clean and Easy

- Clean surfaces and no depositions

- No or very little post treatment required

- No focus control necessary due to long working distance

General Specifications

| Version | LCS 800 | ||

| Working volume | mm (W x D x H) | 690 x 630 x 100 | |

| Accuracy (after compensation) | µm (X,Y) | +/- 8 | |

| Repeatability | µm (X,Y) | +/- 5 | |

| Number of axes | 3-axis | ||

| Laser Type | Diode pumped solid state Nd:YAG, pulsed | ||

| Wavelength | nm | 532 | |

| Dimensions (machine w/o arm, screen and signal tower) | mm (W x D x H) | 1960 x 1650 x 2000 | |

| Dimensions (utilities cabinet) | mm (W x D x H) | 700 x 2300 x 1600 | |