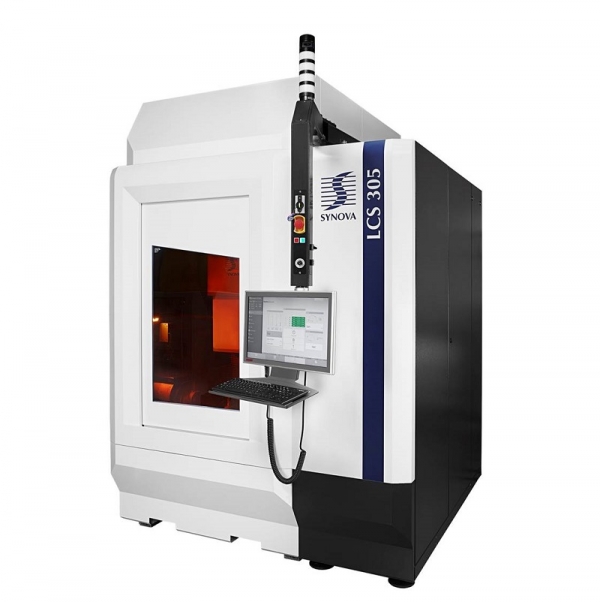

The LCS 305 with 5 axes is specifically designed for the automatic production of larger and multi-tooth diamond cutting tools. The CNC machine with five synchronous axes is characterized by a particularly intelligent machine concept and highly dynamic axes for maximum precision and speed.

The LCS disposes of consistent temperature control with water-cooled linear and torque motors (+/- 0.1°C) and a mineral casting machine bed for more stability and reduced vibrations.

A fully automatic offset calibration system integrates laser-nozzle alignment, automatic jet angle correction, laser power meter and touch probe.

Tools can be exchanged with a very high accuracy thanks to the HSK 63 tool holder.

Materials

Hard materials: Polycrystalline CBN (PcBN), polycrystalline diamond (PCD), single crystalline diamond (SCD), chemical-vapor-deposition (CVD) diamond, natural diamond (ND), tungsten carbide (WC)

Metals: Superalloys, stainless steel, aluminium, copper, titanium, nickel etc.

Ceramics: Ceramic-matrix composites (CMCs), silicon carbide (SiC), silicon nitride (SiN), zirconia (ZrO2), HTCC/LTCC (high temperature and low temperature co-fired ceramic), aluminum nitride (AlN), aluminum oxide (Al2O3)

Operations

3D cutting, shaping, drilling, slotting, grooving, trenching, milling, slicing, edge grinding (K-land edges, single or multiple clearance angles) engraving, profiling

Key Benefits

- Sharp and Smooth

- Smooth cutting surfaces and sharp edges (Ra as low as 0.2 μm)

- Cylindrical beam resulting in parallel kerfs (no V-shape)

- Virtually no heat impact thanks to water jet cooling capability

- Fast and Accurate

- Finnish cutting of 1.6 mm PCD and cemented carbide in 3 mm/min.

- High mechanical precision with a tolerance of +/- 5 μm

- Very small kerf width (down to 30 μm)

- Clean and Easy

- Clean surfaces and no depositions

- No post treatment required

- No focus control necessary due to long working distance

General Specifications

| Version | LCS 305 | |||

| Maximum stroke | mm (X,X,Z) | 500 x 380 x 380 | ||

| Accuracy* (after compensation) | µm (X,Y) | +/- 5 | ||

| Repeatability* | µm (X,Y) | +/- 2 | ||

| Number of axes | 5-axis | |||

| Laser Type | Diode pumped solid state Nd: YAG, pulsed |

|||

| Wavelength | nm | 532 | ||

| Dimensions machine | mm (W x D x H) | 1800 x 1950 x 2610 | ||

| Dimensions cabinet | mm (W x D x H) | 700 x 2300 x 1600 | ||

* only if temperature controlled room